News Center

The layout of the clean room

2026/2/4

The main classification of its layout method can be based on "functional zoning logic", "cleanliness level gradient", and "process movement layout", as follows:

I. Division according to "Functional Zones and Cleanliness Gradient" (Core Layout Principle)

The core risk of a cleanroom is "pollution penetration from the lower cleanliness area outside to the higher cleanliness area inside". Therefore, the primary principle of the layout is to follow the gradient principle of gradually increasing cleanliness levels from outside to inside, achieving pollution control through zone isolation. The common layout methods include the following 3 types:

1. Single-zone layout (suitable for low cleanliness requirements and a single process)

Definition: The entire cleanroom is an independent clean area with no obvious internal cleanliness gradient. Pollution is controlled only through "cleanroom - non-cleanroom" peripheral isolation (such as buffer rooms, air showers).

Applicable scenarios: Cleanliness levels are low (such as ISO 8-9), the process is simple, and there is no zoning requirement. For example, ordinary electronic component assembly, food packaging workshops.

Layout characteristics:

The planar structure is simple, and the area is usually small (generally ≤ 100㎡);

Only 1-2 auxiliary facilities (such as changing rooms, air showers) need to be set at the entrance, without internal zoning partitions;

The air flow organization is mostly "random flow" (not single-direction flow), which is low in cost, but cannot meet the high cleanliness requirements. Advantages and Disadvantages:

Advantages: Simple design / construction, low cost, high space utilization;

Disadvantages: Poor uniformity of cleanliness level, unable to isolate cross-contamination (such as dust and volatile gases) between different processes.

2. Multi-zone Series Layout (suitable for high cleanliness requirements, linear processes)

Definition: Divide the cleanroom into multiple series of independent zones in a gradient of "non-clean zone → low-clean zone → medium-clean zone → high-clean zone", with each zone connected by "buffer rooms, transfer windows, and airlock rooms", forming a unidirectional clean passage to avoid cross-contamination.

Applicable scenarios: Scenarios with high cleanliness requirements (such as ISO 5-7 levels), and linear process flow (such as "raw material pre-treatment → core processing → testing → packaging"), such as semiconductor chip manufacturing, and sterile formulation workshops in biopharmaceuticals.

Layout features:

The clean zones are connected in series according to the process sequence, with personnel / materials flowing "from low-clean to high-clean" in a unidirectional manner, and not reversible;

The high-clean zone (such as ISO 5 level) is usually located at the innermost position, farthest from the non-clean zone, to reduce external interference;

The "static pressure difference" between adjacent zones needs to be strictly controlled (the high-clean zone has a positive pressure relative to the low-clean zone, usually with a pressure difference of ≥ 5 Pa), to prevent air from the low-clean zone from infiltrating.

Example: Typical series partition of a biopharmaceutical workshop:

Non-clean zone (corridor) → First change room (normal zone) → Second change room (ISO 8 level) → Buffer room (ISO 7 level) → Sterile operation zone (ISO 5 level) → Sterile packaging zone (ISO 5 level).

3. Core Zone Encircling Layout (suitable for extremely high cleanliness requirements, critical processes)

Definition: Place the highest cleanliness level "core process zone" (such as ISO 4 level and above) at the center, and surround the medium-clean zone, low-clean zone, and auxiliary zone from the outside, forming a "concentric circle" of cleanliness gradient, to minimize the impact of external pollution on the core zone.

Applicable scenarios: Extremely high cleanliness requirements (such as ISO 3-4 levels), and scenarios where the core process is extremely sensitive to pollution, such as microelectronic chip lithography area, biosafety level 3 (BSL-3) laboratory, and stem cell cultivation workshop.

Layout features:

The core zone adopts "unidirectional flow" (laminar flow) air (such as vertical laminar flow, horizontal laminar flow), with the air flowing from the core zone to the low-clean zone on the outside, forming an "air flow barrier";

The core zone has no direct external openings, and personnel / materials need to enter through "multiple levels of buffering + transfer windows", and undergo strict purification treatment (such as personnel wearing sterile suits, materials sterilization);

Auxiliary facilities (such as air conditioning rooms, vacuum pump rooms) are usually located at the outermost position to avoid vibration and noise interference to the core zone.

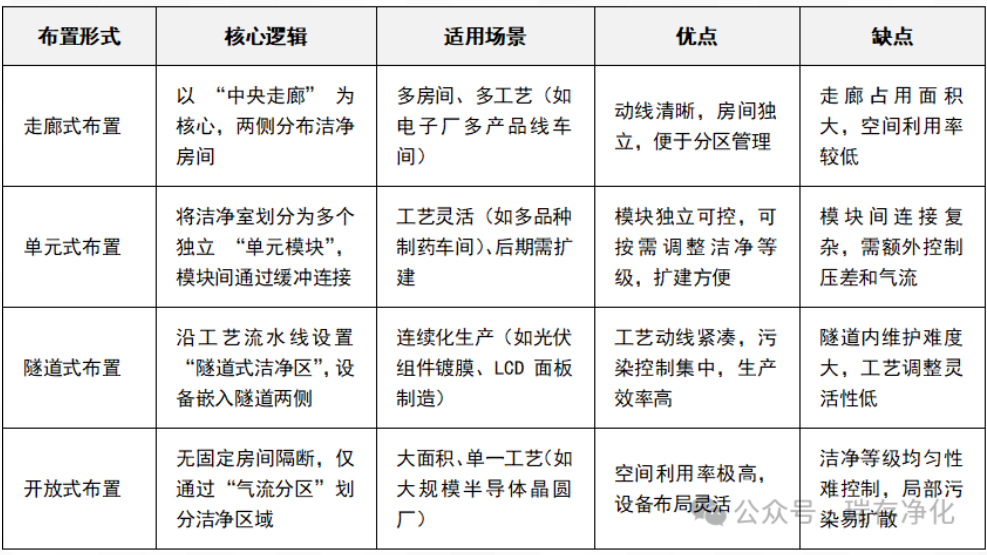

Based on the clean gradient, it is necessary to optimize the floor plan by combining the "personnel flow, material flow, and equipment layout" of the production process. The common practical forms include the following 4 types:

Regardless of the layout method adopted, the following core requirements must be met to ensure the effective functionality of the cleanroom:

Line Separation Principle: Clearly distinguish "personnel movement path", "material movement path", and "product movement path", avoiding cross-over (for example, personnel move from the changing room to the clean area, while materials move from the material entrance to the transfer window and then to the clean area, with no overlap), and preventing the contamination of materials/products by the personnel's contaminants.

Minimum Area Principle: The area of the clean area should "just meet the process requirements", avoiding excessive size (the larger the area, the higher the energy consumption for controlling pollution and maintaining the cleanliness level); non-clean auxiliary areas (such as changing rooms, rest rooms) should be arranged on the outside of the clean area to reduce the area of the clean area.

No Dead Angle Design: The junctions of the walls, floors, and ceilings of the cleanroom need to adopt "rounded corners" (radius ≥ 50mm), avoiding right angles where dust accumulates; doors need to be well-sealed (such as using sealing rubber strips), and the opening direction of the door should face the higher cleanliness area (to prevent the door from not closing due to pressure difference).

Auxiliary Facilities Accommodation: On the outside of the clean area, a "cleaning auxiliary area" needs to be provided, including:

Personnel Cleaning: Changing room (at least 2 levels), air shower / shower room, disinfection room;

Material Cleaning: Material entrance, transfer window (with ultraviolet disinfection), unpacking room (to remove external packaging contamination);

Public Facilities: Air conditioning room (close to the clean area to reduce the length of ducts), pure water station, waste gas treatment device.

In summary, the floor layout of the cleanroom needs to "first determine the cleanliness gradient, then optimize the process movement path", combined with specific industry regulations (such as medicine, electronics, food) and process characteristics, ultimately achieving the goal of "controllable pollution, efficient process, and reasonable energy consumption".