News Center

Summary of Three Different Methods for blocking Pipes through walls

2025/10/10

Standard key points

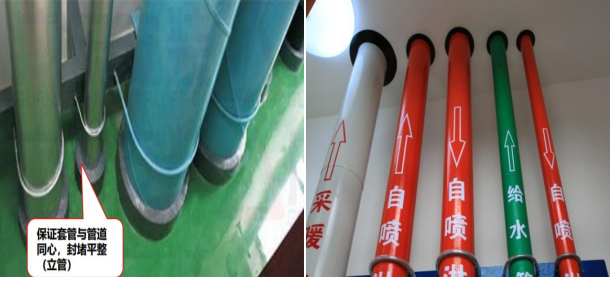

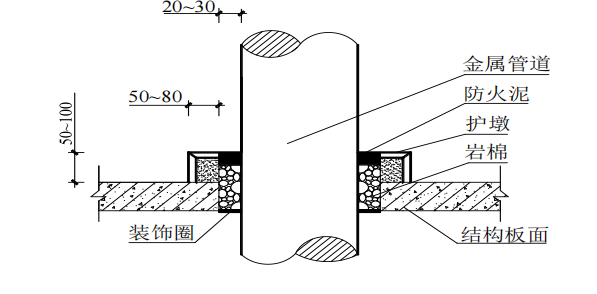

1. The specification of the casing should be two grades larger than the diameter of the pipe.

2. The top of the sleeve installed in the floor slab is 20mm above the ground. When installed in bathrooms and kitchens, it should be 50mm above the ground and the bottom should be flush with the bottom surface of the floor slab. The two ends of the sleeve installed in the wall are flush with the decorative surface.

4. The casing and the passing pipe should be concentric.

Before installing pipes in the pipe well, the ceiling and wall decoration and renovation works must be completed to avoid the situation where the wall decoration and renovation works cannot be carried out after the pipe installation is completed.

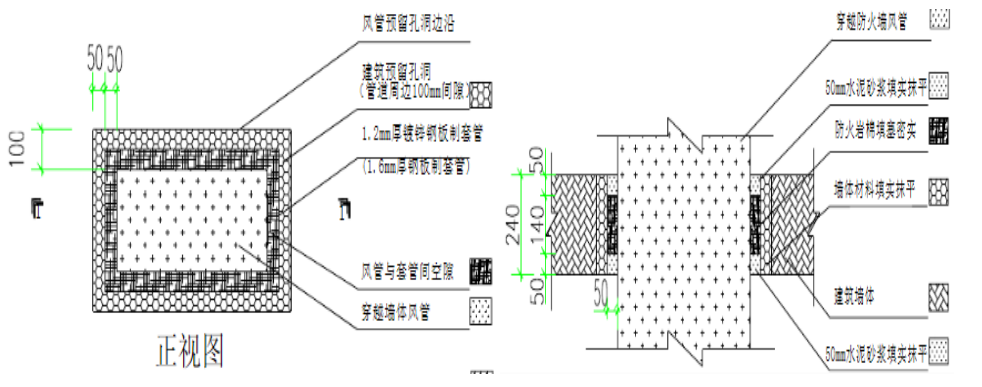

Methods for Blocking Air Ducts through Walls

1. Air duct sleeve: When air ducts pass through fireproof or explosion-proof walls or floors that need to be enclosed, 1.6mm thick embedded pipes or sleeves should be installed.

3. Before installing pipes in the pipe well, the decoration and renovation of the top plate and walls must be completed.

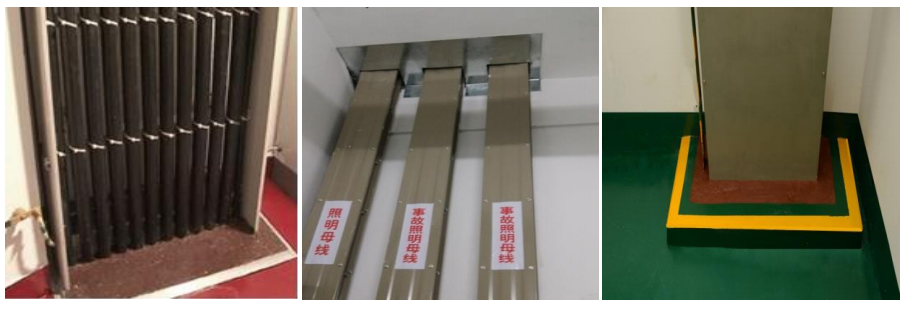

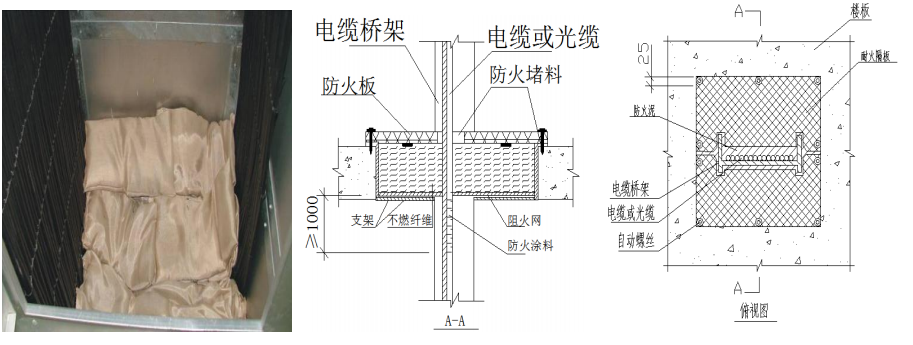

Fireproof Sealing Methods for Cable Trays in Pipe shafts

1. When cable trays pass through fire compartments, fireproof sealing should be carried out.

2. The cable tray should not be connected in the floor slab, and the cover plate should be staggered from the floor slab by 200-300mm to facilitate fireproof sealing. When crossing the floor slab simultaneously, a waterproof platform should be added around for protection, with a height of no less than 50mm.

4. Before installing pipes in the pipe well, the ceiling and wall decoration and renovation works must be completed to avoid the situation where the wall decoration and renovation works cannot be carried out after the pipe installation is completed.