News Center

Definition standards and requirements for Class 1,000 cleanrooms

2025/7/16

01 Magnitude of Pressure

Cleanrooms must maintain a certain relative positive pressure, and the pressure between cleanrooms of different grades should not be less than 5Pa. The pressure between the cleanroom and the non-cleanroom should be no less than 10Pa to prevent the air from the low-level cleanroom from flowing back into the high-level cleanroom.

The temperature should be maintained at 18 to 26 degrees Celsius

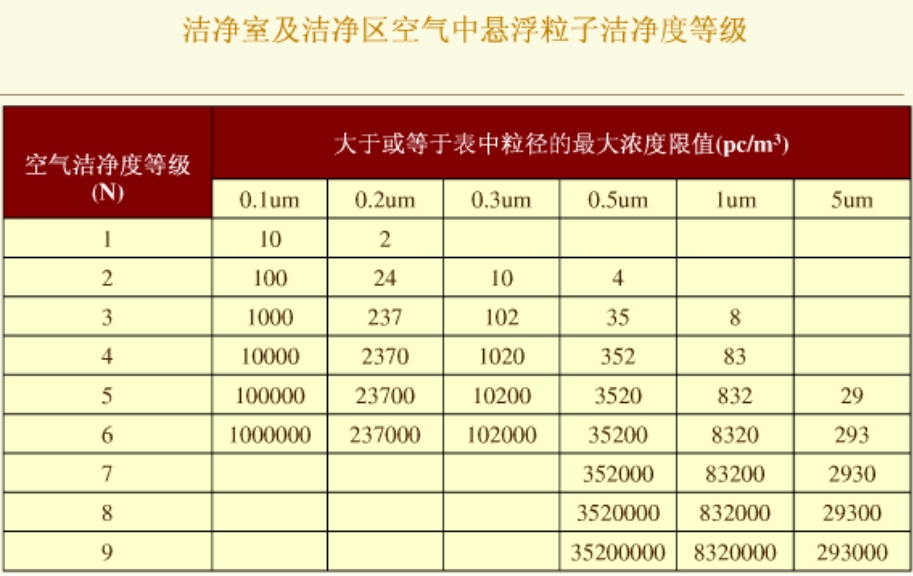

According to international practice, the level of dust-free purification is mainly determined by the number of particles with diameters larger than the classification standard per cubic meter of air. That is to say, so-called dust-free does not mean there is absolutely no dust at all, but rather it is controlled within a very tiny unit. Of course, the particles that meet the dust standard in this standard are already extremely small compared to the common dust we see. However, for optical structures, even a tiny bit of dust can have a very significant negative impact. Therefore, in the production of optical structure products, dust-free is an inevitable requirement. If the number of particles with A diameter of less than 0.5 microns per cubic meter is controlled to be below 3,500, it will meet the international dust-free standard of Grade A.

A dust-free workshop refers to a specially designed room where pollutants such as micro-particles, harmful air, and bacteria in the air within a certain space range are removed, and the temperature, cleanliness, indoor pressure, air flow velocity and distribution, noise and vibration, lighting, and static electricity inside the room are controlled within a certain required range. That is to say, regardless of how the external air conditions change, the indoor environment can maintain the originally set requirements for cleanliness, temperature, humidity and pressure, etc.

To achieve a good clean effect in a cleanroom, it is not only necessary to focus on taking reasonable air conditioning and purification measures, but also requires corresponding measures from the process, architecture and other specialties: not only should there be a reasonable design, but also meticulous and standardized construction and installation, as well as correct use of the cleanroom and scientific maintenance and management.

Dust-free workshop purification system

Air purification systems can be classified into three types: horizontal laminar flow, vertical laminar flow and turbulent flow. The form of the selected airflow should be chosen based on the design layout and requirements.

The cleanliness of each room in the clean room and the ventilation time depend on the number of ventilation times within a certain period. Therefore, carefully consider that the working requirements of each room in the purification workshop may be different, as well as the production process, and then determine the technical parameters of the purification system.

To ensure that the airflow is almost undisturbed, it is necessary to carry out structural design and layout of the workshop to prevent the generation of airflow vortices. When necessary, caution should be exercised to prevent unnecessary incidents from occurring.

When determining the design plan, the first step is to carefully consider the nature of the room's work and the air flow conditions, understand the overall layout and requirements. The workshop uses a large amount of dust, and rooms with high cleanliness requirements should be as far away as possible from other workshops to avoid the formation of ground air.

The materials used for the walls and floors in Workshop 05 must be dust-free, corrosion-resistant, heat-resistant, not prone to cracking, and not likely to generate static electricity. The choice can also be made based on the different working conditions of the room and the actual situation.

The control of personnel and objects in a cleanroom is the main source of dust in a dust-free workshop. Of course, production equipment also generates dust, but people and objects are the sources of dust.

Cleanliness grades of biological cleanrooms

Cleanrooms are classified according to the degree of air cleanliness. If the grade of a cleanroom is only described by the number of dust particles, it can be assumed that the size of the dust particles is 0.5μm. For example, the maximum number of dust particles in Class 1, Class 10, and Class 100 cleanrooms is less than or equal to 1, 10, and 100 respectively. If the dust particle size is not 0.5μm, the cleanroom grade should be expressed by the number of grades at a specific dust particle size, which are respectively divided into Class 1, Class 10, Class 100, Class 1000, Class 10000, and Class 100000. The smaller the value, the higher the purification level. The higher the cleanliness, the higher the cost.

The requirements for cleanliness grades in various industries

Class 1 cleanroom: Mainly used in the microelectronics industry for manufacturing integrated circuits, the precision requirement for integrated circuits is sub-micron.

Class 10 cleanroom: Mainly used in the semiconductor industry where the bandwidth is less than 2 microns.

Class 100 cleanroom: It can be used for aseptic manufacturing processes in the pharmaceutical industry, etc.

Thousand-level purification workshop: Mainly used for the production of high-quality optical products, and also for testing, assembling aircraft gyroscopes, assembling high-quality miniature bearings, etc.

Class 10,000 cleanroom: It is mainly used for the assembly of hydraulic or pneumatic equipment. In some cases, it is also used in the food and beverage industry. Besides, Class 10,000 cleanrooms are also commonly used in the medical industry.

Class 100,000 cleanroom: Class 100,000 cleanrooms are widely used in many industrial sectors, such as the manufacturing of optical products, the production of small components for large electronic systems, the manufacturing of hydraulic or pneumatic systems, the production of food and beverages, and are also frequently employed in the medical and pharmaceutical industries.