News Center

A brief introduction to the design of purification HVAC

2025/5/23

Firstly, purification HVAC design is a key technology to ensure that environmental parameters such as air quality, temperature and humidity in a specific space meet specific requirements. In fields such as medicine, electronics and biotechnology, this kind of design is particularly important because it is directly related to the quality of the product, the stability of the production process and the health of the operators.

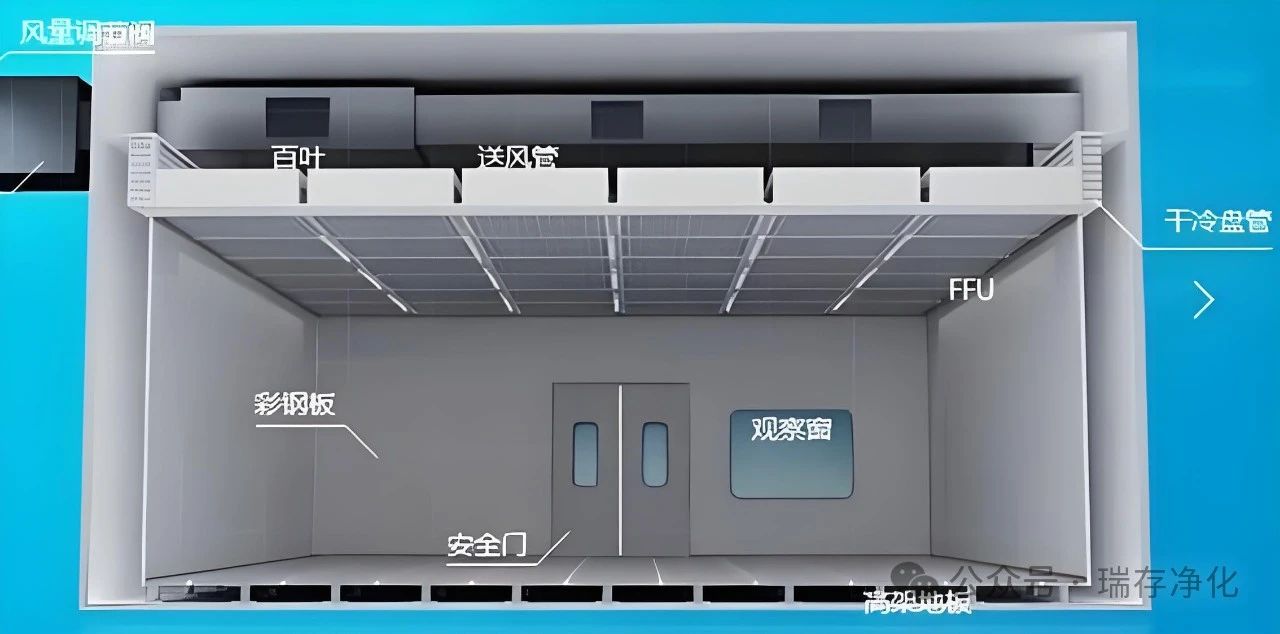

Under normal circumstances, a purification HVAC system mainly includes three aspects: air purification, temperature and humidity control, and air flow organization. Air purification is achieved through a multi-stage filtration system, including primary, medium and high-efficiency filters, which can effectively remove dust particles, microorganisms and other pollutants in the air. Temperature and humidity control ensures that the indoor environment fluctuates within the set temperature and humidity range through processing methods such as heating, humidification, and cooling, to meet the requirements of production processes or human comfort. Air flow organization is achieved through reasonable design of supply air, return air and exhaust air to ensure uniform distribution and effective circulation of indoor air, avoiding adverse air flow phenomena such as vortices and dead corners.

In the design of purification HVAC, special attention should be paid to the flexibility and stability of the system. As different production areas may have different requirements for purification levels, the system should have the ability of zonal control and be capable of adjusting parameters such as supply air volume, temperature and humidity according to actual needs. Meanwhile, the system should also have a high degree of stability to ensure that environmental parameters remain stable and are not disturbed by the outside world during long-term operation.

In actual design, customized design is also needed based on specific usage scenarios and requirements. For instance, in an electronics factory, as the products have strict requirements for molecular-level pollutants in the air, it is necessary to add special treatment equipment such as chemical filters to the system. In hospital operating rooms, it is necessary to ensure that the airflow in the surgical area flows in one direction to avoid the risk of cross-infection.