News Center

The importance of dust-free environment control in clean rooms

2025/5/23

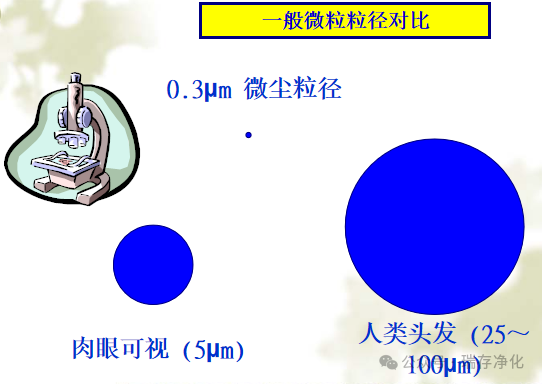

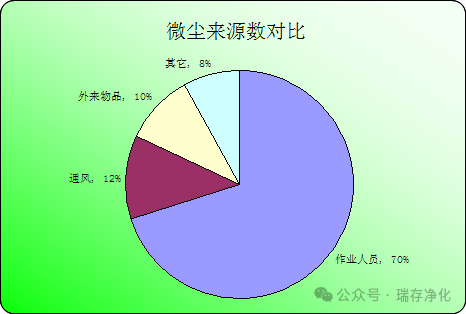

The sources of particles are classified into inorganic particles, organic particles and living particles. For the human body, it can easily cause respiratory and lung diseases, and at the same time, it can also cause allergies and viral infections. For silicon chips, the adhesion of fine dust particles can cause deformation or short circuits in integrated circuit lines, causing the chips to lose their operational functions. Therefore, the control of micro-pollution sources has become an important part of cleanroom management.

1) . Ensure product quality

1. Pollution prevention: In industries such as semiconductors, pharmaceuticals, and medical equipment, tiny particulate pollutants may cause product defects or failures. By controlling the air quality and particle concentration in the clean room, the impact of these pollutants on the products can be effectively avoided.

2. Consistency: The cleanroom environment helps maintain the consistency and repeatability of the production process, thereby ensuring stable product quality. As for the glass substrate, the adhesion of fine dust particles will cause scratches, short circuits and bubble adhesion on the glass substrate, resulting in poor process quality and scrapping. Therefore, the control of pollution sources has become an important link in the management of clean rooms.

External dust intrusion and prevention: Maintain an appropriate positive pressure in the cleanroom (>0.5mm/Hg), ensure no air leakage during the initial construction work, and take dust prevention measures such as cleaning and wiping before bringing personnel, equipment, raw materials, tools, and consumables into the cleanroom. At the same time, cleaning tools should be properly placed and replaced or cleaned regularly.

Dust generation and prevention in cleanrooms: Appropriate selection of cleanroom materials such as partition boards and floors, control of the occurrence of process equipment and regular maintenance and cleaning, production personnel are not allowed to walk around or make large body movements at their positions, and special sites should take preventive measures such as adding sticky dust MATS.

2) . Enhance production efficiency

1. Reduce the rate of defective products: By reducing impurities and pollutants in the production process, the rate of defective products can be lowered, the yield of finished products can be increased, and thus production efficiency can be enhanced.

For instance, there are 600 steps in wafer production. If the yield rate of each process is 99%, what is the overall yield rate after 600 process procedures? Answer: 0.99600 = 0.24%. In order for a program to be economically feasible, one may ask how high the yield of each step needs to be? •0.999600= 54.8%, •0.9999600=94.2%. The yield of each process needs to reach above 99.99% to ensure that the final process yield is greater than 90%, and the contamination of micro-particles will directly affect the process yield.

2. Accelerate the process: Working in a clean environment can reduce unnecessary cleaning and rework time, making the production process more efficient.

Occupational health: For some production processes that may release harmful substances, clean rooms can prevent the spread of harmful substances to the external environment and protect the health of workers. Up to now, human beings have made technological progress, advanced equipment and improved knowledge levels, but the air quality has deteriorated. A person inhales approximately 270,000 cubic meters of air throughout their life and spends 70% to 90% of their time indoors. Tiny particles are inhaled by the human body and deposit in the respiratory system. Particles ranging from 5 to 30 μ m deposit in the nasopharynx, those ranging from 1 to 5 μ m deposit in the trachea and bronchi, and those smaller than 1 μ m deposit on the alveolar walls.

Staying in an indoor environment with insufficient fresh air for a long time can easily lead to "indoor syndrome", causing symptoms such as headache, chest tightness and easy fatigue, and also easily triggering diseases of the respiratory and nervous systems. According to the national standard GB/T18883-2002 of our country, the fresh air volume should not be less than 30m ³ /h. Person.

The fresh air volume of the cleanroom should be the maximum of the following two items:

The sum of the air volume required to compensate for the indoor exhaust volume and ensure the positive pressure value inside the room.

b. Ensure the supply of fresh air required by the staff in the clean room. According to the "Code for Design of Clean Rooms", the fresh air volume per person per hour shall not be less than 40 cubic meters.

2. Safe production: By controlling environmental parameters such as humidity and temperature, potential safety hazards like static discharge can be avoided, ensuring production safety.

4) . Meet the requirements of regulations and standards

1. Industry standards: Many industries have strict cleanliness standards (such as ISO 14644), and production must be carried out in cleanrooms of specific grades. Meeting these standards is not only a regulatory requirement but also a reflection of an enterprise's competitiveness. For clean workbenches, clean booths, laminar flow transfer Windows, fan filter units (FFUs), clean wardrobes, laminar flow hoods, weighing hoods, clean screens, self-cleaning devices, and air shower series products, it is necessary to standardize the methods for testing the cleanliness of existing products to enhance the credibility of the products.

2. Certification and Audit: Pass the audit of a third-party certification body to obtain relevant certifications (such as GMP, ISO 9001, etc.), enhance customer trust, and expand market access.

5) . Promoting Technological Innovation

1. Research and development support: Cleanrooms provide an ideal experimental environment for the research and development of high-tech products, which helps accelerate the development process of new products.

2. Process optimization: Under strictly controlled conditions, it is easier to observe and analyze the impact of process changes on product performance, thereby promoting process improvement.

6) . Enhance brand image

1. Quality Assurance: Possessing high-standard clean production facilities can enhance the brand image and increase customers' trust in product quality.

2. Market competitiveness: Products that can be produced in a clean environment are usually regarded as symbols of high quality and high reliability, which helps enterprises stand out in the fierce market competition.

7) . Reduce maintenance and repair costs

1. Extend equipment lifespan: Production equipment and tools operating under clean conditions are less prone to corrosion and wear, thereby extending their service life and reducing maintenance frequency and costs.