News Center

Introduction to clean room raised floor

2025/1/8

The opening rate of elevated floor is one of the key factors to determine its ventilation performance. According to different application requirements and design standards, the opening rate of the elevated floor can be selected differently. Common opening rates include 17%, 25% and 50%. The selection of these opening rates is based on the consideration of ventilation volume, wind speed, and pressure difference.

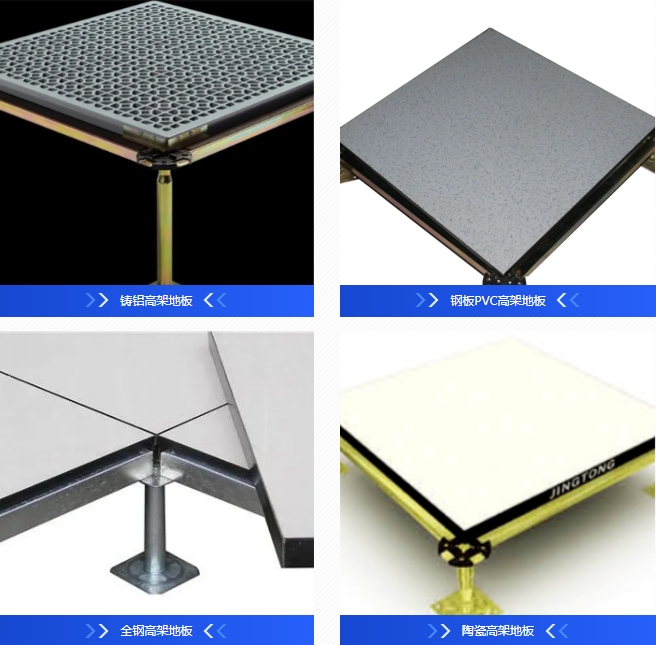

The raised floor has anti-static and non-anti-static points, and the clean room of the electronic industry clean room generally has anti-static requirements. What is the elevated anti-static floor? The elevated anti-static floor is mainly composed of adjustable brackets, beams, panels, etc., and there is a certain hanging space between the horizontal floor and the panel. It can be used for lower wiring and return air, with strong bearing capacity, wear-resistant, waterproof, fireproof, dust-proof, anti-static and other characteristics, suitable for electronic workshop, semiconductor workshop, optical workshop, constant temperature laboratory, hundred-level dust-free workshop. In addition, according to the different requirements of the use of the movable floor, the carrying capacity of the unit square meter is different, and the form and specification of the elevated floor should be selected according to the use requirements during construction.

Clean workshop (dust-free workshop) overhead anti-static floor construction precautions:

The elevated anti-static floor and its supporting structure should meet the design and load-bearing requirements;

The elevation of the laying ground shall meet the design requirements;

The surface of the ground should be smooth, smooth, dust-free, moisture content is less than 8%, and paint according to the design requirements;

The surface layer and supporting parts of the elevated floor should be smooth and solid, moisture-proof and mildew proof, inflammable or non-inflammable, aging resistance, acid and alkali resistance, electrostatic conductivity and other characteristics;

The opening rate and distribution of an elevated ESD floor must meet the design requirements.

Precautions for maintenance and maintenance of anti-static raised floor:

It is forbidden to walk on the floor with shoes with nails;

It is strictly prohibited to carve hard objects and hardware on the floor, especially around the equipment transportation route and installation equipment to liner plywood, as well as scratches and oil stains on the floor;

After the floor construction is completed, it is strictly prohibited to drag the machine and equipment on the floor when handling the machine and equipment;

Do not use corrosive solvents to wash the floor surface;

Production work area should wear soft sole special shoes or foot cover into the work area, strictly prevent dust into the workplace;

It is strictly forbidden to pollute the floor surface with permeable ink and mechanical oil;

Strictly prevent the heavy trailer dragging on the floor surface, the tires selected by the production site car as far as possible to avoid the easily decolorized vinyl tires, nylon tires are recommended;

The surface of the floor is polluted, clean the surface of the floor with gasoline, washing and cleaning powder, and then polish the surface with anti-static wax;

The floor is generally cleaned once a year, and then on the anti-static floor wax polishing maintenance treatment.

The cleaning under the raised floor of the clean room can be carried out by the following steps:

Daily cleaning: push dust and clean the ground in stages from inside to outside. In the cleaning of the ground garbage, gum and other timely with anti-static agents and dust-free cloth clean. If there are stains or water marks, use a nano-sponge wipe or nano-sponge mop head dipped in water to wipe, and you can clean the dirt without wiping with the diluent of the floor oil cleaning agent.

Monthly cleaning: cleaning once every two weeks to a month, a small range can be used to scrub the nano-sponge mop, if the workshop area is too large, can be used with a disk washing machine and other equipment cleaning, to ensure that the ground is clean without dust and stains.

Annual cleaning: every six months to a year, according to the need to use different cleaning agents for different stains to clean, the polishing surface material can be deeply cleaned with a disk washing machine, with brightening agent to ensure that there is no missing work no dead corners.

Special precautions: Avoid contact with the black rubber cushion chair to prevent black sulfide contamination of the floor. Wash with neutral detergent and keep the surface clean. Do not contain sharp, heavy friction, drag on the floor surface, do not wear shoes with nails on the floor to walk, keep the floor surface smooth and smooth.