News Center

Analysis of the problems and countermeasures of electromechanical control valve in small opening operation

2024/11/14

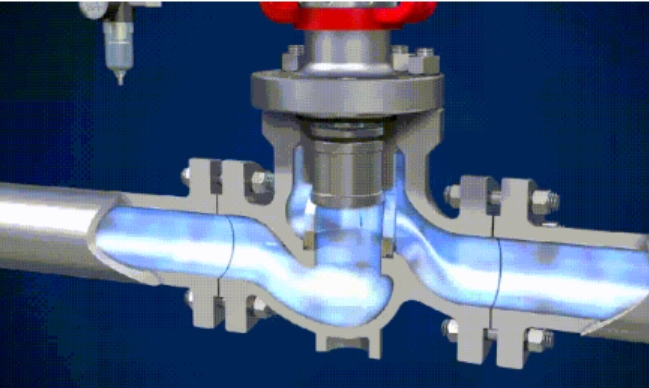

There are sharp changes in flow resistance, flow rate, pressure and so on when the regulating valve is working with a small opening, which will bring the following problems:

① The throttle gap is the smallest, the flow rate is the largest, and the erosion is the most severe, which seriously affects the service life of the valve;

② Sharp flow rate, pressure changes, exceed the stiffness of the valve, valve stability, and even produce serious oscillation;

③ For the valve working in the flow closed state, it will produce a jump close or jump start phenomenon, and the regulating valve cannot be adjusted in this opening;

④ The opening degree is small, and the spool sealing surface is close to the throttle port, which is harmful to the spool sealing surface;

⑤ Some valves are not suitable for small opening work, if the butterfly valve, small opening unbalance torque is large, will produce jump jump off phenomenon, such as two-seat valve, two spool one in the flow open, one in the flow close, small opening when the stability is poor, easy to produce oscillation.

In summary, in order to improve the service life, stability, normal regulation and other workability of the valve, the regulating valve should avoid working in a small opening, usually greater than 10% to 15%. However, for high-pressure valves, two-seat valves, butterfly valves, and regulating valves in the flow closed state, they should be greater than 20%(linear valves)~30%(logarithmic valves).

When the valve selection is large or the process conditions change, the regulating valve often works under a small opening, how to solve it at this time?

① Reduce the pressure differential ΔP on the valve. It can be seen from the equation Q=C√ΔP/P that when ΔP decreases, Q also decreases. In order to keep the flow rate through the regulating valve unchanged, the opening of the valve must be increased, so as to avoid the valve working at a small opening. The specific methods are as follows:

a, add a limiting orifice plate behind the valve to consume part of the pressure drop;

b, close the manual valve in series on the pipeline until the regulator achieves a larger ideal working opening.

Both methods increase the pressure drop on the pipe to reduce the pressure drop on the valve, because the total system pressure drop ΔP system = pressure drop on the valve ΔP valve + line pressure drop ΔP line. Because the ΔP system is unchanged, when the ΔP pipe increases, the ΔP valve must decrease.

② From Q=C√ΔP/P, it can be seen that the C value decreases, and Q also decreases. In order to keep the flow rate through the valve unchanged, it is necessary to increase the opening, which can also avoid the valve working at a small opening. The C value is related to the diameter DN of the valve and the diameter dN of the seat. The method of reducing C value is:

a, change a small caliber valve, such as DN32 to DN25;

b, the valve body is unchanged, change the small gear DN spool seat, such as DN10 to DN8.

When the regulator is working at a small opening, the following problems may occur:

1.Easily blocked: In the small opening, the fluid flow rate is slow, easy to make the fluid particles deposited in the flow channel of the regulator, resulting in valve blockage or stuck.

2. Unstable flow control: In the case of small opening, the flow control of the regulator may become not stable enough and is susceptible to external interference or internal factors, resulting in flow fluctuations or inaccurencies.

3. Flash and oscillation: When the fluid passes through the regulator at a small opening, flash may occur, resulting in dramatic changes in fluid pressure and temperature, and may also cause valve oscillation.

Countermeasures include:

1. Choose the right type of valve: For situations that need to work at a small opening, you can choose some regulating valves specially designed for small flow, such as micro-regulating valves, to reduce the possibility of clogging.

2. Add filters and mesh: Filters or mesh can be installed to prevent particles from entering the flow path of the regulator and reduce the risk of clogging.

3. Optimize the design and material of the valve: The valve structure with reasonable design and corrosion resistance can reduce the sensitivity to particle blockage.

4. Increase the bearing range of the valve: combined with the regulating valve and control system, the bearing range of the valve can be increased, thereby improving the control accuracy and stability under small opening.

5. Enhanced overhaul and maintenance: Regular inspection and maintenance of regulating valves, timely cleaning of pipes and filters, can reduce the risk of clogging.

By choosing the valve type reasonably, taking effective anti-blocking measures and strengthening the maintenance and maintenance of the regulating valve, the problems that may occur when the regulating valve is working at a small opening can be effectively solved.