News Center

Correct installation and use of differential pressure gauges

2024/11/6

The installation and commissioning of the pressure differential gauge is one of the important and necessary links to ensure that the pressure differential and cleanliness in the clean room are up to standard, so the correct installation and use of the pressure differential gauge is particularly important.

1, the use of differential pressure gauge

The air differential pressure meter is suitable for the measurement of air micro-pressure difference, and it is widely used in the detection and display of environmental micro-pressure difference in pharmaceutical and microelectronics industries. The differential pressure meter can be embedded or mounted on the outside of the wall of the clean room, without power supply, high sensitivity and high measurement accuracy.

2. Measure the pressure

Use an air duct to connect the pressure source to either of the two high-pressure mouths and block the unused one; Aerate one or two low pressure openings.

Differential pressure measurement: the high pressure source is connected to any one of the two high pressure mouths with the airway, and the low pressure source is connected to any one of the two low pressure mouths with the airway; Plug the two pressure taps on the table that are not used.

Measure negative pressure: Connect the pressure source with any one of the two low pressure mouths with the airway, and block the one that is not used; Aerate one or two high-pressure ports.

3, the installation of the differential pressure meter

Generally, the installation panel of 2MM thick 304 stainless steel differential pressure gauge can be selected. After installation, there are no exposed parts, which makes the overall appearance and easy installation and maintenance.

Generally, the pressure difference is detected between the clean room and the non-clean room, and the installation location is generally the wall between the clean room and the non-clean room to facilitate the pressure difference between the inside and outside of the clean room. The red oil differential pressure meter should be installed horizontally when installing the pointer differential pressure meter, and pay attention to the zero adjustment. In addition, pay attention to the direction of the nozzle of the differential pressure meter.

If the clean room is a positive pressure room, the high pressure end of the differential pressure meter is connected to the clean room, and the low pressure end is not connected; If the clean room is a negative pressure room, the low pressure end of the differential pressure meter is connected to the clean room, and the high pressure end is not connected.

4, red oil pressure differential meter installation steps

The installation of the pressure differential meter needs to be installed in a certain order, and can not be installed at will, which easily leads to the installation of the pressure differential meter can not be used. The detailed installation procedure is as follows:

Fixed differential pressure meter: There are two mounting holes on the differential pressure meter, which need to be installed on the wall using screws, and can also be installed on the vertical plane.

By adjusting the horizontal position, the water bubble inside the horizontal column is located in the middle position.

Loosen the top zero knob 3~4 turns, here you can mark the reading circle.

Inject red oil into the differential pressure meter: It is necessary to remove the plug of the injection hole, and then fill the red oil from the injection hole until the liquid reaches the 0 scale stop, and tighten the plug.

Fine tuning red oil differential pressure gauge for zero processing. When the red oil is stabilized, the zero point above can be kept flat with the red oil level by twisting the zero knob under normal pressure.

The last part is very critical, it is necessary to use the hose of the red oil differential pressure meter to connect the High pressure and Low pressure and the corresponding "high" and "low" air inlet of the differential pressure meter in turn, so that the differential pressure meter is completely installed.

5, pointer type differential pressure meter installation steps

The instrument shall be installed perpendicular to the horizontal plane of the air purification project;

The measuring point of the instrument and the instrument installation are in the same horizontal position, whether to consider the correction of additional height error;

The distance between the instrument installation and the measurement point should be as short as possible to avoid slow indication;

Ensure tightness, there should be no leakage phenomenon;

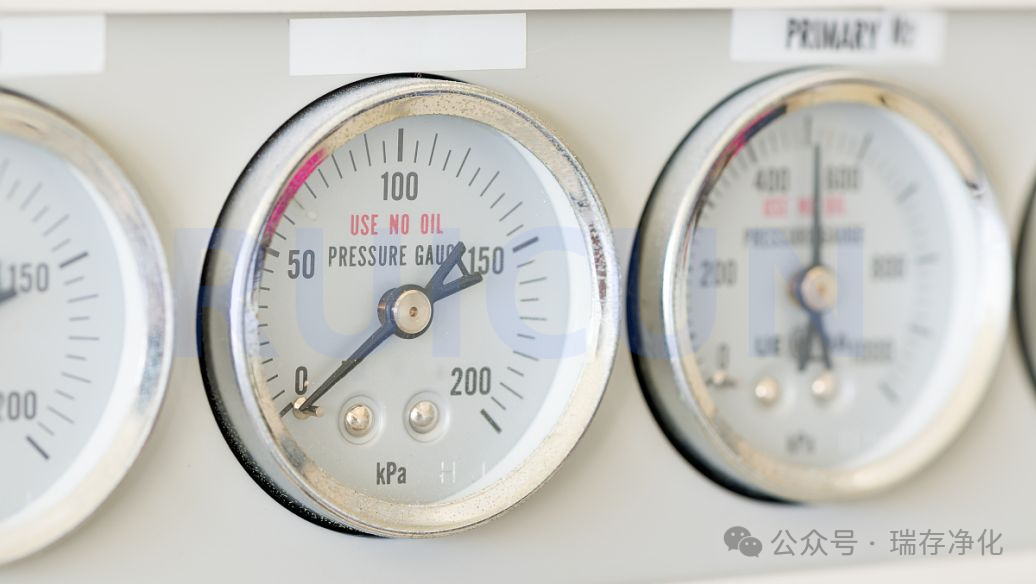

For the newly purchased pressure detection instrument, it is necessary to carry out metrology verification before installation and use to prevent vibration, damage or other factors from destroying the accuracy of the pressure instrument during transportation.

In addition to clearly specifying the room and equipment with differential pressure requirements, the process requirements should also be considered. From the perspective of cost and management, the differential pressure meter is set as little as possible. The general differential pressure meter should be placed in the low level area, and the gas pipe should be placed in the high level area. Filling and corridor, clean area and general area, high level clean area and low level clean area, etc.

Please pay attention to the following points:

Where the cleanliness level is different, a differential pressure meter should be installed in order to prevent cross contamination. Under normal circumstances, the position where there is air flow between the clean area and the unclean area and between different clean levels must be installed with the differential pressure indicator device, such as the place where the conveyor belt is opened.

Both sides of the primary effect filter and medium effect filter of the air conditioning system should also be installed to test whether the filter is intact.

Do not set the pressure difference too high, large energy consumption. For example, it is recommended that the pressure difference in Class A area be maintained at about 60Pa and not more than 100Pa. The pressure difference setting adjustment is first adjusted from the innermost room, that is, the highest level of pressure difference is first determined, and slowly reduced to the outside.

It is not recommended to install a differential pressure meter in the cross-level transfer window. The transfer window should belong to the air lock setting and install laminar flow. It is meaningless to install a differential pressure gauge to measure the different level areas at both ends of the transfer window, and it is also meaningless to measure the two ends of the transfer window. Since both sides of the transfer window should not be opened at the same time, there will be no air flow, so the differential pressure indicator device can not be installed. However, enterprises should regularly test and maintain the transmission window to ensure the tightness of the transmission window.

The aseptic packing room shall have a device indicating pressure difference and monitor the visiting corridor of the general area.