News Center

Study on clean room heating ventilation and smoke control system

2024/11/6

Keywords: clean room, heating and ventilation, smoke control and exhaust, system design, safety performance

Moreover, the above normative clause is a mandatory clause, which states in the interpretation of the clause: In the domestic existing clean room survey, in order to prevent pollution caused by radiators, in addition to a small number of reconstruction projects using the original radiator for clean room heating, the new clean room does not use radiator heating, taking into account the development of technology, it is stipulated that including 8 and more than 8 clean rooms should not use radiator heating.

Therefore, the current clean room heating basically uses the combined air conditioning system, and the heating function section is added in the combined clean air conditioning system, such as electric heating, steam heating, hot water heating, etc.

The ventilation requirements of clean rooms are mainly reflected in the control of indoor temperature, humidity, cleanliness and air flow organization. The ventilation system needs to meet the working comfort requirements of clean room personnel and ensure the normal operation of clean room equipment. In addition, the ventilation system should also have the characteristics of energy saving, low noise and easy maintenance.

The design of clean room ventilation system should follow the following principles: First, ensure that the indoor air quality meets the cleanliness requirements; Secondly, organize air flow reasonably to avoid dead corners and vortices; Thirdly, use efficient and energy-saving ventilation equipment to reduce energy consumption; Finally, ensure the stability and reliability of the system operation.

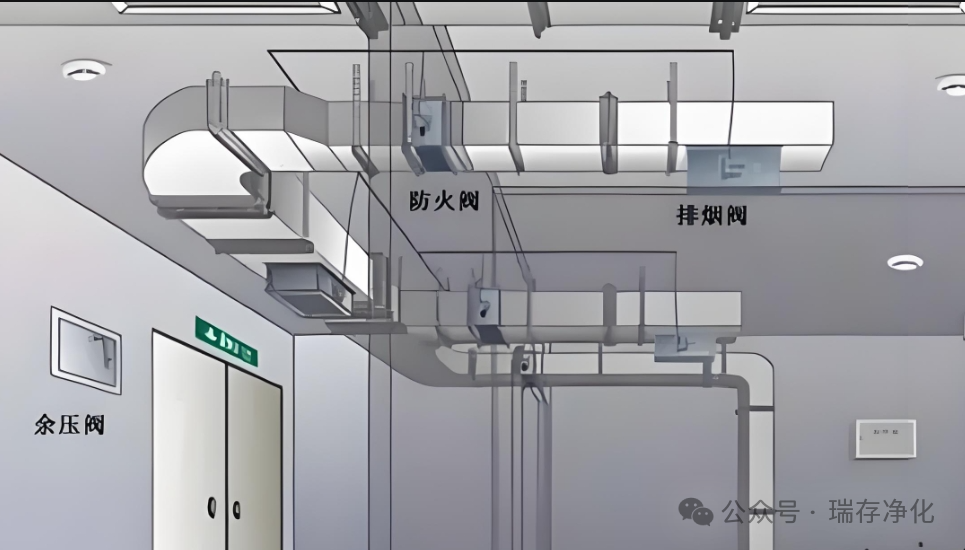

Clean room ventilation system mainly includes air supply system, return air system and exhaust air system. The supply air system is responsible for sending the treated fresh air into the clean room, the return air system is responsible for recycling the indoor air, and the exhaust air system is responsible for discharging the indoor polluted air. All systems should be coordinated to ensure stable air quality in the clean room.

In emergency situations such as fire, smoke control and exhaust system plays a vital role in ensuring personnel safety and reducing property losses. Effective smoke control and exhaust system can quickly eliminate smoke, reduce the speed of fire spread, and provide favorable conditions for personnel evacuation and fire rescue.

2. Design points of smoke control and exhaust system

The design of smoke control and exhaust system should consider the building structure, use function, fire risk and other factors of clean room. The key points of design include: reasonable division of smoke prevention zones to ensure that smoke can be quickly discharged; Select suitable exhaust equipment, such as exhaust fan, exhaust port, etc. Set up effective fire isolation measures to prevent the spread of fire; And set up automatic fire alarm and linkage control system to achieve automatic management.

3. Operation and maintenance of the smoke prevention and exhaust system

The smoke control and exhaust system should be kept in good condition during daily operation, and inspected and maintained regularly. The operation and maintenance contents include: check the operation status of the smoke exhaust equipment regularly to ensure its normal operation; Regularly clean the exhaust port and exhaust pipe to prevent clogging; Test the automatic fire alarm and linkage control system regularly to ensure its reliability.

Aiming at the energy consumption of clean room heating, ventilation and smoke control and exhaust system, a series of energy-saving optimization measures can be adopted. For example, the use of energy-efficient ventilation and smoke exhaust equipment to reduce energy consumption; Use heat recovery technology to improve energy efficiency; Set parameters such as temperature and humidity properly to avoid energy waste.

2. Intelligent management

Intelligent management system is introduced to realize automatic and intelligent management of clean room heating, ventilation and smoke control and exhaust system. Through real-time monitoring of indoor environment parameters and equipment operating status, automatic adjustment of system operating mode, improve the stability and reliability of system operation.

3. Improved security performance

Strengthen the safety performance of clean room smoke control and exhaust system, improve the fire prevention and smoke exhaust capacity of the system. For example, the selection of high-temperature and corrosion-resistant smoke exhaust materials to improve the durability of smoke exhaust equipment; Set up multiple fire isolation measures to prevent the spread of fire; Improve the automatic fire alarm and linkage control system to ensure timely response in emergency situations such as fire.

Clean room heating, ventilation and smoke control system is the key technology to ensure the operation safety and environmental quality of clean room. Through in-depth analysis of the ventilation and heating needs of clean room and the importance of smoke control and exhaust system, this paper puts forward effective measures to optimize the heating and ventilation and smoke control system of clean room. In the future, with the continuous development of science and technology, the clean room heating, ventilation and smoke control and exhaust system will be further intelligent, efficient and safe, providing more reliable technical support for the operation of the clean room.