News Center

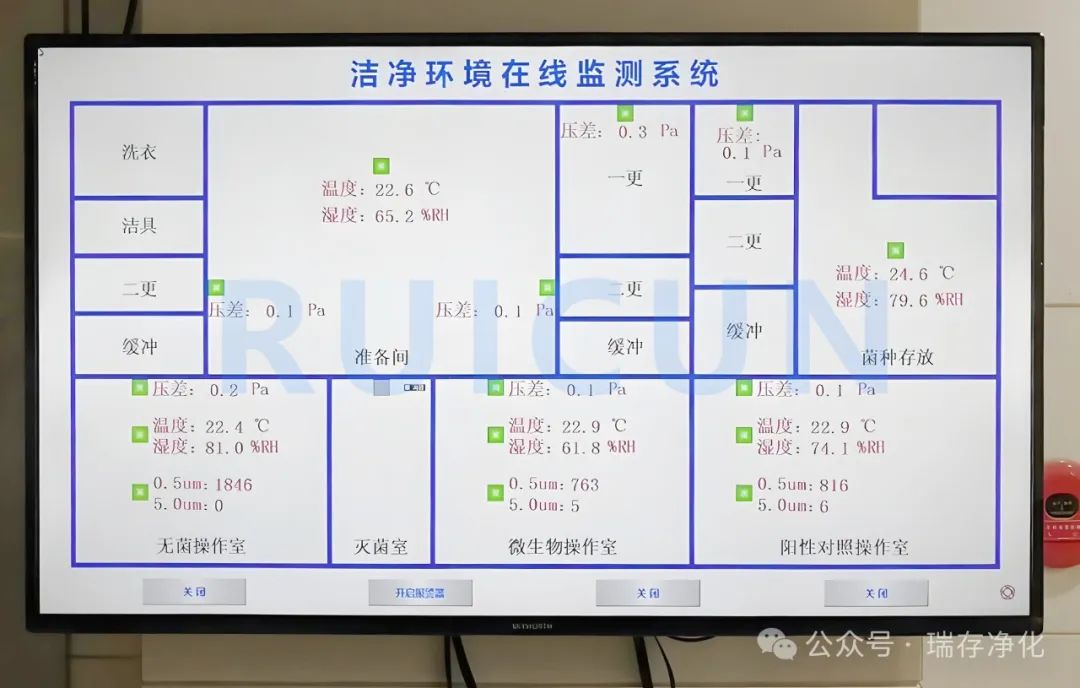

Clean room dust particles online monitoring distribution

2024/10/31

Regarding the online monitoring of clean room dust particles, when sales engineers carry out technical exchanges with customers, the most common question asked by customers is: you do this is professional, according to your on-site installation experience, combined with domestic and foreign regulations, how to arrange these points, which places must be distributed, which places can not be distributed? This question seems to be a very normal problem, but to answer this question is not so simple, from a variety of regulations, and does not explain how many points a production line should be arranged, nor does it clearly say which places must be arranged, or vice versa which points can not be arranged.

Of course, to arrange the point, we must first understand that the purpose of online monitoring of our dust particles - whether the environment is controlled, and then according to the method of risk assessment, according to their own production process, combined with the company's various management procedures, so the dust particle distribution as a production enterprise must also be involved in the final determination of the distribution point.

Although there are no regulations that clearly specify the specific number and location of locations, there are relevant guidance, such as the American Society of Pharmaceutical and Health Sciences (PHSS) Best Practice Guide for Online Monitoring of Dust Particles in the Pharmaceutical Industry, which recommends the recommended points for risk assessment:

In summary: in the production process, the place where the drug is exposed in the air, the place where the operation is intervened by people, and the packaging materials (bottles, plugs) and production-related equipment that are in direct contact with the drug are the location of the distribution point we should consider. For Class B area, it is recommended to monitor in A way similar to the monitoring of class A area, but the frequency of monitoring can be reduced, so we usually in the B+A production line, according to the classification of air conditioning and the purpose of dust particle monitoring - whether the environment is controlled, the general filling room B background can be monitored online. The sampling points of the online monitoring system should take into account the nature of the equipment, the behavior of the operator and the process of drug production, and determine the most valuable monitoring points of the online monitoring system through the risk assessment of contamination in different locations.

The following factors should be taken into account when determining monitoring sites: Where the work place is near the work place, the possibility of the product being exposed to the air during the production process, the possibility of operator interference in which areas of personnel activity in a certain part of the sampling operation is sufficient to cause error in the test data or contamination of the product Where microbial contamination is most likely to have an adverse impact on the quality of the product during the production process, When determining the specific location of the sampling point, it should also be determined according to the actual production situation, according to the equipment layout and the operation position of the actual personnel, after risk assessment.