News Center

Electronic workshop clean room engineering construction technical requirements

2024/8/30

Code for Clean Plant Design (GB 50073-2001)

Design Code for Heating, Ventilation and Air Conditioning (GB50019-2003)

Design Code for Electronic Industry Clean Workshop (GB50472-2008)

"Ventilation and air conditioning Engineering construction Quality Acceptance Code" (GB50243-2002)

Code for Construction and Acceptance of Industrial Metal Pipeline Engineering (GB50235-97)

General Code for Construction and Acceptance of Mechanical Equipment Installation Engineering (GB50231-98)

Code for Construction and Acceptance of Thermal Insulation Works for Industrial Equipment and Pipelines (GBJ126-89)

Standard for Quality Inspection and Evaluation of Ventilation and Air Conditioning Engineering (GBJ304-88)

Refer to the test acceptance standard: ISO 14644-2

1, detailed construction technical requirements refer to HVAC professional construction drawing design drawings and general instructions.

2. After receiving the construction plan of the plant building, the construction unit shall draw the purification panel (wall panel) layout drawing and ceiling panel layout drawing within one week in accordance with the construction drawings, and submit them to the design unit and the owner for review and approval.

3, Before the construction of the clean room system, the construction unit needs to write the "clean room construction and installation management regulations", and report to the owner and supervision unit for review and approval. And strictly implement the "provisions" in the whole process of clean room installation and construction.

4. Before purchasing materials, the construction unit shall submit material samples (including integrated sample of clean room roof, wall panel, window and door), material technical parameters, test report and other documents to the engineering design unit, the owner and the supervision unit. Obtain the owner's approval before the formal purchase.

5, clean room delivery, return air pipe are using plug-in flange connection. The air leakage rate shall not exceed 1%. The thickness of the steel plate and the distance between the supports and hangers must meet the requirements of the relevant construction acceptance specifications and the general instructions for HVAC design and construction.

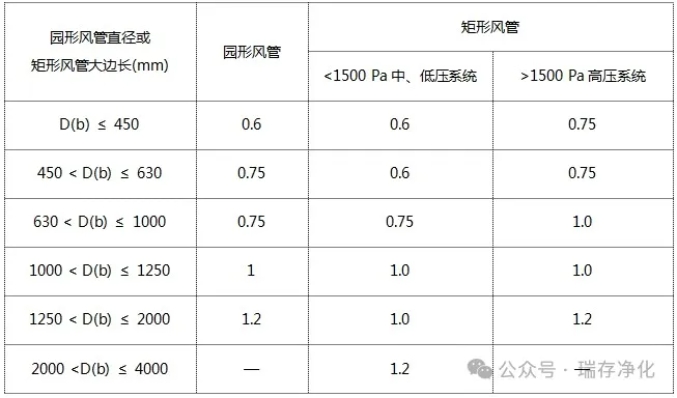

The thickness of galvanized steel plate meets the following requirements:

7. The construction unit shall establish a cleaning site before air duct installation at the air duct installation site; Install immediately after cleaning. The air duct after cleaning shall be installed within the working period of this installation team.

8, air duct support bracket spacing where not indicated on the drawing, should comply with the following provisions:

1) Horizontal installation: If the diameter or large edge of the air duct is less than 400mm, the spacing does not exceed 4m; Greater than or equal to 400mm, spacing does not exceed 3m; Insulation air pipe, spacing does not exceed 3m.

2) Vertical installation: no insulation air pipe, spacing does not exceed 4m; The distance between the insulation air pipes shall not exceed 3.5m, but the fixed parts of each riser shall not be less than two.

3) The support bracket shall not be set in the tuyere, valve and inspection door; The hanger shall not be directly hung on the flange, and the production and installation of the air duct support hanger shall be made in accordance with the national standard Atlas 03K132.

4) If the air duct connected to the high efficiency air supply outlet is a hard pipe, it is necessary to use 100~200mm flexible short pipe to connect with it, and the material should be made of flexible, non-dust, non-air permeability and non-static electricity, such as smooth artificial leather, soft rubber sheet, light facing inside.

5) The gasket of the flange of the air duct is made of rubber plate or closed-cell sponge rubber, and the thickness is not less than 5mm.

6) The detachable interface on the air duct cannot be located in the wall or floor.

7) The air duct support hanger should be set outside the thermal insulation layer, and the support bracket and the air duct should be inlaid with anti-corrosion cushion wood, and avoid setting the support bracket in the air valve, flange and other parts.

8) The appearance quality, flexibility and reliability of the fire control valve should be tested before installation, and the installation should be confirmed after passing. A separate support hanger should be set up during installation, and the requirements of the fire code should be strictly followed.

9) The elbow with the large side length of the air duct >500mm should be equipped with a deflector.

10) The air duct is strictly prohibited from using ordinary black iron bolts, and should use galvanized bolts or stainless steel bolts.

11) All axial fan outlets need to be equipped with movable metal shutter tuyere, see national standard 94K101-1.

9. Air duct rust removal, heat preservation and fire prevention requirements

1) Rust prevention: Air pipes made of galvanized steel plates are generally not painted. The pipe metal support bracket shall be cold galvanized U-shaped steel support bracket.

2) Insulation: In addition to the air duct from the fresh air outlet to the air conditioner is not insulated, the rest of the air duct is insulated with high foam rubber and plastic insulation sheet, fire rating must be ≥B1, wet resistance factor >4500; The thickness of rubber and plastic insulation sheet is selected according to the relevant specifications according to the cross-section size of the air pipe.

3) The exhaust pipe of the hot exhaust system shall be insulated, and the insulation shall be made of centrifugal glass wool with aluminum foil (48kg/m3) with fire rating ≥A1, and the part of the purification area shall be outsourced with aluminum plate 0.6mm thick. The exhaust pipe connected to the cooling room exhaust system should be insulated. Centrifugal glass wool with aluminum foil (48kg/m3) with fire rating ≥A1 should be used for insulation, and aluminum plate 0.6mm thick should be outsourced. The exhaust pipe connected to the exhaust system in the annealing furnace room shall be insulated. The insulation shall be centrifugal glass wool with aluminum foil (48kg/m3) with fire rating ≥A1, and the aluminum plate with 0.6mm thickness shall be outfitted. The smoke exhaust pipe connected to the mechanical smoke exhaust system in the room should be insulated. The insulation should adopt non-flammable centrifugal glass wool with aluminum foil (48kg/m3) with fire rating ≥A1, and the aluminum plate with 0.6mm thickness should be outsourced.

10, purify air conditioning pipe water pipe material; Accessories, insulation materials, silencing materials and binders are made of non-combustible materials or non-combustible materials, and soft joints of air pipes are made of non-combustible materials or non-combustible materials. When the pipeline passes through the firewall, the gap around it should be filled with non-combustible materials, and the smoke exhaust pipe in the ceiling should be insulated, and the insulation material should be non-combustible materials. Fire valve should pay attention to the installation direction, set a separate support.

11, clean room ceiling construction must use laser leveling instrument for horizontal leveling calibration.

12, the high efficiency air filter must be installed after the clean room forms an air-tight space, the "clean" stage is completed, and the air is blown for at least 12 hours. According to the tight construction and process equipment moving in period of this project, it is recommended that the HEPA filter be installed after the process equipment is moved in and the outer packaging is removed to avoid pollution or damage to the filter.

13. The construction unit of this bid section shall construct the wear-resistant anti-static PVC block floor in the clean room, including the ground pole (copper rod) led from the indoor copper foil guide grid to the outdoor ground pole (including the ground pole). The grounding resistance is less than 1 ohms.

14. The gluing process in the construction of wall panels and ceiling panels must be tested by the construction unit and approved by the owner and supervision unit before large-scale construction. Otherwise, the rework caused by unqualified glue quality (not full, not flat, uneven line width, etc.) shall be responsible for by the construction unit. Silicone should be neutral silicone.

15, in principle, all the holes in the clean room wall panel and top plate should be completed in the factory, and do a good job. In special cases (such as when professional conditions do not exist), you can use the on-site drilling method to accurately locate the site. However, special tools must be used to open holes on site.